From Gibson catalog “Q.” Lloyd Loar, center, at his workbench.

“shape this brace to this” Photo (top) courtesy Christie Carter, taken while at Gruhn Guitars, Nashville, TN. This writing was found on the underside of the soundboard of F-5 72211, next to the treble brace (tone bar). Photo (bottom) courtesy Steve Gilchrist. A view of finished braces, inside back of Gibson F-5 73982.

“Shape this brace to this (followed by a sketch)” was written in ink on the underside of the top by the treble brace of Gibson F-5 72211. Lloyd Loar’s handwriting, in cursive, on his draft card registration and passport application confirm a match to this writing. Analyses of the writing on similar documents of the other woodworkers employed at Gibson in 1922 reveal no matches.

On the maple back of Gibson F-5 71634, FON 11789, in the same hand, is written “thin slightly” and an arrow is drawn to a place on the back where some thinning was executed after the initial sanding.

In interviews and correspondence with a colleague (who will be profiled extensively in a future edition of Breaking News 1922) working with Lloyd Loar in 1922, Loar was described as “obsessed with detail. Very opinionated.” He was always making sure everything was done just so, and had his eye on every aspect of the manufacture of mandolin and banjo family instruments.

The writings that Loar published, and in the patents granted to him, one theme is consistent: a desire for equal balance in all frequency ranges. Every note, from lowest to highest, should be as powerful as all the others. Even in the best of the oval hole Gibsons, the power and projection of the treble notes are never equal to the bass. With two f-holes centered on either side of the bridge in an arched top carved skillfully to precise thicknesses, the mandolin comes closer to this idea of balance. The shape of this brace was yet another element to achieve tone in the treble.

(note: it is rare to examine closely the underside of the top of a Loar F-5. How many more handwritten instructions are there that we have never seen? Does your F-5 have hidden notes written inside?)

Photo from Gibson catalog “L” published in 1919. Close inspection identifies James M. Johnstone on left.

In 1922, Gibson Mandolin and Guitar Factory employed a team of highly talented woodworkers; details below include age, job description and language in 1922.

Victor Kraske, 65, foreman. Speaks reads and writes English. Born Germany October 1857. Immigration: left port at Amsterdam, arrived Ellis Island on the “Castor” February 5, 1883. By 1896 listed as foreman at Barrows Music Company in Saginaw Michigan. On a patent granted on January 11, 1898, he was listed as inventor of an f-hole mandolin. Barrows Music Company, which produced musical instruments including aluminum banjos and mandolins, engaged Orville Gibson to provide inlay work during the period in which Kraske was foreman there. From 1902 to 1905, the Victory Kraske Company produced musical instruments in Chicago, including f-hole mandolins under the “Waldo” brand. In 1906, Kraske became foreman at Gibson Mandolin and Guitar Co., and remained in that position until he left Gibson in 1926.

Ca. 1906 Gibson Artist model with f-shaped sound holes, about the time Victor Kraske came to work at Gibson. (courtesy Steve Gilchrist)

John S Paterson, 56 , wood carver. Worked at Gibson since 1911; his parents were immigrants from Switzerland; speaks English. Left Gibson in 1925.

John J Voisine, 50, “wood worker.” Born in Canada; speaks French, but not English. Left Gibson in 1925.

John J Voisine, ca. 1922.

Adrian Glerum 23, woodworker. Born 1889 in Holland (Netherlands), arrived in US March 1911. Speaks, reads & writes English. Left Gibson in 1925, but was rehired in 1930s. In a later photo, he is shown tap-tuning a violin prompting some scholars to conclude that his role on the F-5 was to tap-tune tops.

Clyde E Seward, 23, born 1899 Cumberland, Wisconsin; woodworker, left Gibson in 1925; in 1926, took a job as a driver for Taylor Produce.

Francis Harrison Havens, 28, draftsman at Kalamazoo Railway Co, born in Three Rivers, Michigan; second mandolinist of the Gibsonians in 1921 and 1922 and may have worked as draftsman for Gibson in 1922. Was back at Kalamazoo Railway by 1924.

Henry T Reeves, 46, draftsman, born in Indiana. Left Gibson in 1925.

Hans Dorthaus Larsen, 63, cabinet maker, speaks, reads and writes English. Born Gronberg, Vejle, Denmark, immigration 1882. Left Gibson by 1926, died of pneumonia, 1927.

Leroy Clement “Curly” Bramble, 32, assistant foreman, born 1890, Franklin, Michigan. Continued at Gibson in various roles through the 1930s.

Roy McKinley Wiberg, 25, woodworker, born in Michigan. Worked at Gibson 1922-1958.

Charles Wallace Best, 62, Woodworker. Born New York 1860. Woodworker at Gibson at least by 1907, foreman in 1926-1927. Continued as woodworker at Gibson almost until his death in 1937.

William H Soule, 61, woodworker, born in Kalamazoo, Michigan. Worked as woodworker for Ford Manufacturing Company, Kalamazoo, 1902; uncertain when he arrived or left Gibson.

George Altermatt, 49, woodworker. Born 1873 in Illinois, son of Swiss immigrants, speaks English. Later became factory superintendent, retired in 1948.

Bertie W Stratton, 42, woodworker, born 1880 in Michigan, his mother was a French immigrant. Speaks, reads and writes English. Worked at Gibson until 1939.

Hurl George “Rusty” Adams, 32, benchworker, born St. Joseph MI 1890, worked at Gibson at least until through 1957. died 1961.

John Adams, 48, bench worker, born in Michigan, wife Carrie M. Working in finishing in 1920, moved downstairs in 1922; continued as woodworker through the 1930s.

David Wills Landes 59, woodworker, born 1863 Ohio.

Garrett Bos 32, wood turner, born 1890 in Michigan, son of Dutch immigrants, speaks English. Retired from Gibson in the 1960s.

John Kraft, 34, bench worker born Germany 1878, immigration 1883, speaks, reads and writes English. continued at Gibson as woodworker through the 1930s.

Orvil Cyril Kuney, 19, woodworker, born in MI, worked for Gibson through the 1930s.

James Weaver 37, woodworker, born 1885 Indiana.

Glen Owen Cook 34, bench mechanic. Born in 1888 Michigan. Worked at Gibson until the 1950s.

Joseph P Curtis 26, machine operator, born in Canada, speaks French, not English. Worked at Gibson until 1960 in various capacities, ending his career as night watchman.

Unidentified worker, assembling an F-5. From Gibson catalog “Q” published in 1927.

L to R: Thaddeus J. McHugh (former foreman, was construction engineer in 1922); Henry T. Reeves (draftsman).

Thaddeus J. McHugh, 62, was born in Michigan around 1860, son of an Irish immigrant. McHugh is listed as a woodworker for Gibson as early as 1907, and by 1911 was promoted to foreman. He performed many different roles at the Gibson factory during his long tenure there. In 1919 he was a machinist; in 1920 and 1921 he became factory superintendent. In 1922 and 1923, he was construction engineer, and in 1924, machinist. He is known famously as inventor or co-inventor on the patent applications that were filed during his time as superintendent. The bridge and truss rod innovations became industry standards.

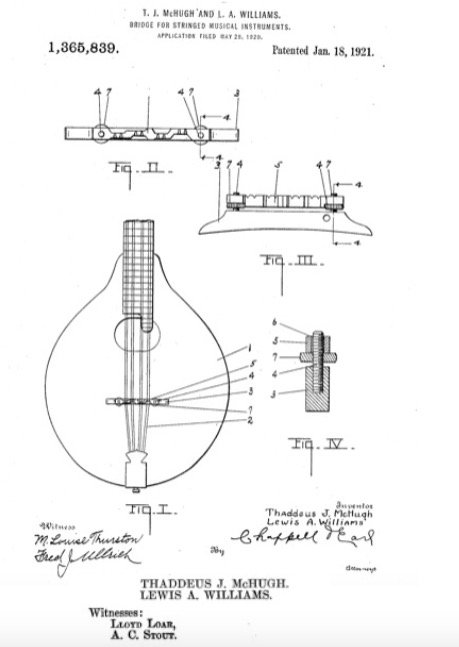

Patent application filed May 28, 1920; Granted January 18, 1921.

Truss rod, patent filed April 5, 1921, granted February 27, 1923.

Gibson Mandola, H-4 # 67403; FON 11605, 1922. In an early attempt to install a truss rod, the double flower pot pearl inlay was cut through to allow for the adjustment slot. Then, as the bottom screw of the truss rod cover hit the metal of the rod, a three-screw cover was installed. We have seen only one other three-screw cover on a Gibson mandolin: on the three-piece neck of an F-5 played by a prominent Bluegrass mandolinist. Do you know which one?

Next week: We head upstairs to witness the creation of a new mandolin finish!